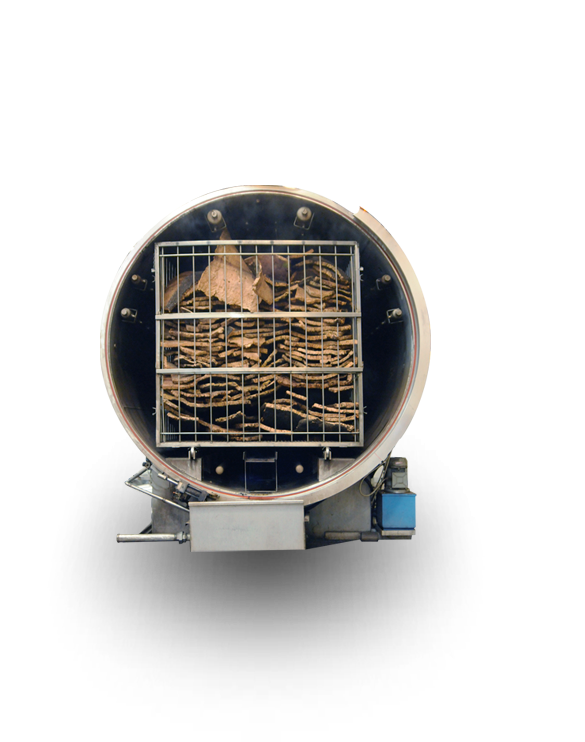

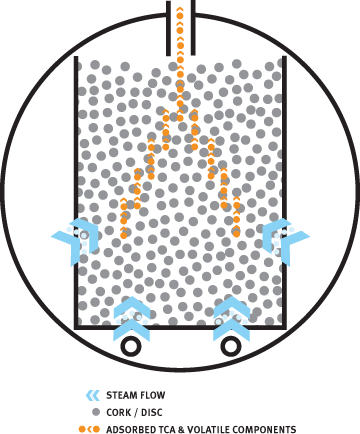

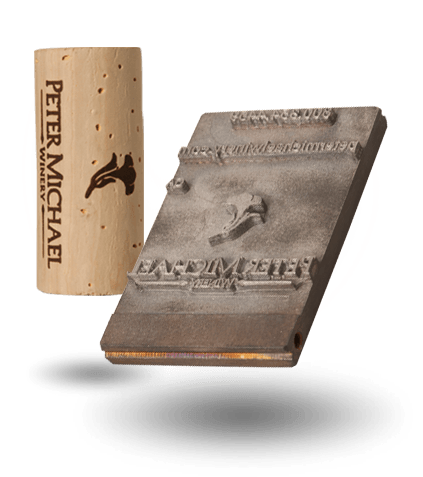

Ganau employs sensory and GCMS screening tests to diligently monitor the presence of TCA in raw and processed cork materials. Ganau soaks thousands of corks on a daily basis, drastically exceeding industry standards in order to study background aromas and TCA concentrations. GCMS tests are performed through production and finished product, ensuring that only the purest corks enter the final production stages.

Beyond TCA screening, Ganau utilizes precision electronic analyzers to measure dimensions, weight and moisture levels of cork products throughout the production process, making certain that the final corks meet both physical and mechanical specifications. Ganau is also well known for its uniform method of grading corks, performed by both specially-trained employees and carefully calibrated electronic eyes.

In applying a wide spectrum of quality control measures, Ganau relies upon modern technology and skilled employees to provide winemakers with some of the purest and highest-quality corks in the world.